What is screen printing?

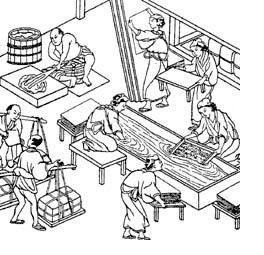

The printing is done through template or stencil-type matrix placed on a permeable silk that allows the ink to pass through the areas not blocked with the stencil, the design is transferred to the silk by various methods, either by blocking directly on the silk the non-printable areas with a brush or spatula and using vinyl glue, another method consists of cutting paper templates or lightweight waterproof materials as stencils and adhering the templates to the silk, this is the process used in Chicha posters that is a popular technique in Peru. Also for processes of photographic type or from digital files, positives printed on photographic material such as lith are used, where the area to be printed is black. To transfer these images to silk, a photosensitive emulsion is applied directly to the silk. and extended with a squeegee or emulsifying racket in order to have a thin and uniform film, when the emulsion dries, the positives are prepared, these are placed against the silk and illuminated for a certain period, in this way the areas of the emulsion affected by light are fixed and the areas blocked by the design in the positive prevent the passage of light preventing the photosensitive reaction, the frame is removed and it is subjected to a stop bath with water where the unilluminated areas are easily removed by rubbing or by the pressure of the water jet, thus creating the reserve areas and printing areas.

Thank you for explaining to us that screen printing involves using a template or a stencil-type matrix on a permeable piece of silk that will allow the ink to pass through the unblocked areas and transfer the design. My high school class is planning a reunion party soon, and we were thinking of getting t-shirts to commemorate the occasion. I’ll be sure to consider screen printing once I find a service provider to hire for our commemorative t-shirts soon.